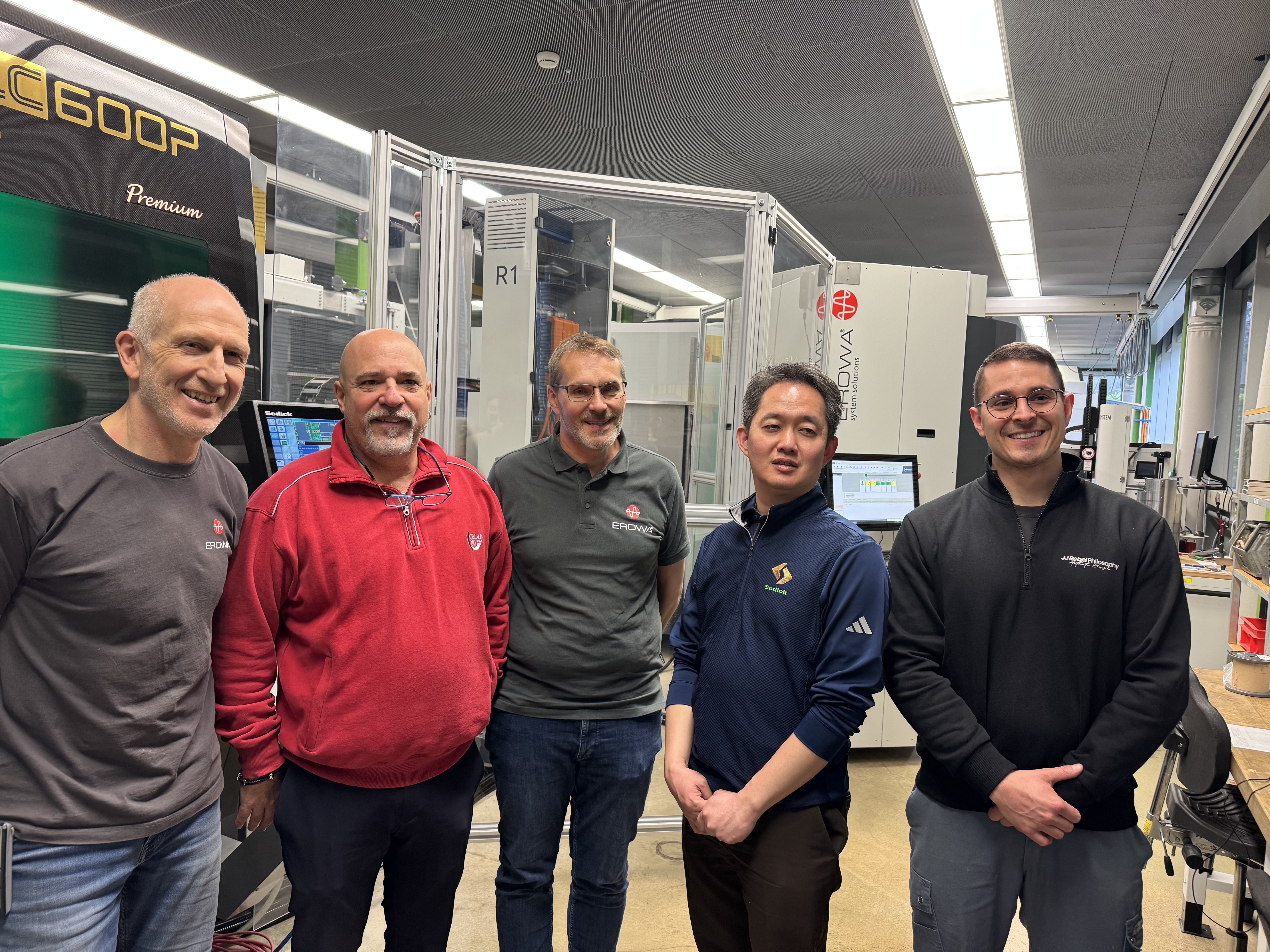

Reinach, Switzerland — Sodick Europe recently facilitated a technical visit to Switzerland, bringing industry media together with manufacturing specialists to showcase advanced automation and wire EDM technology operating in a real production environment.

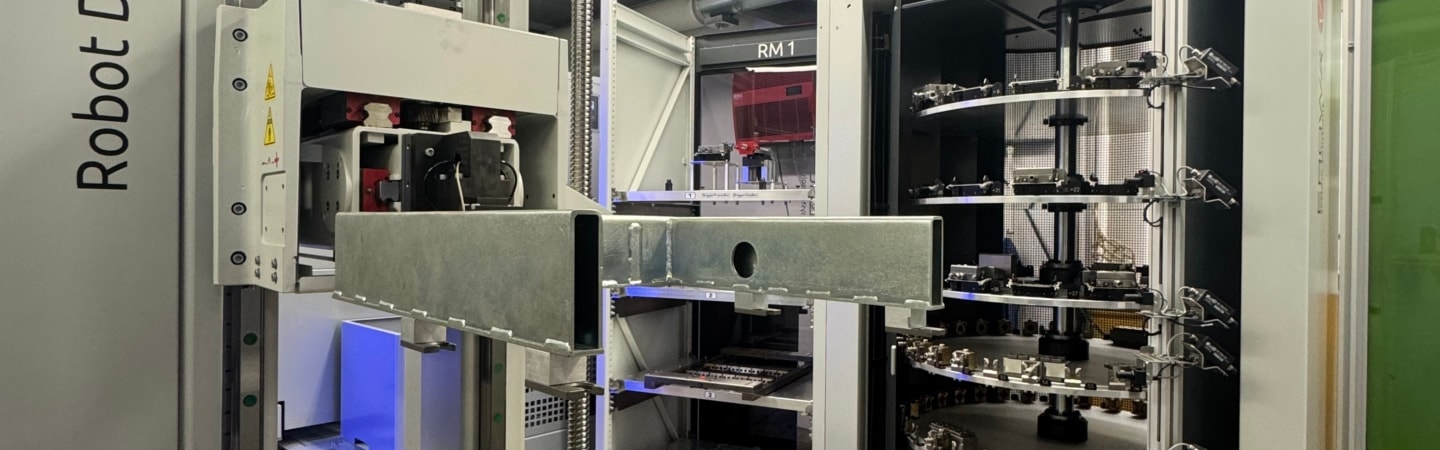

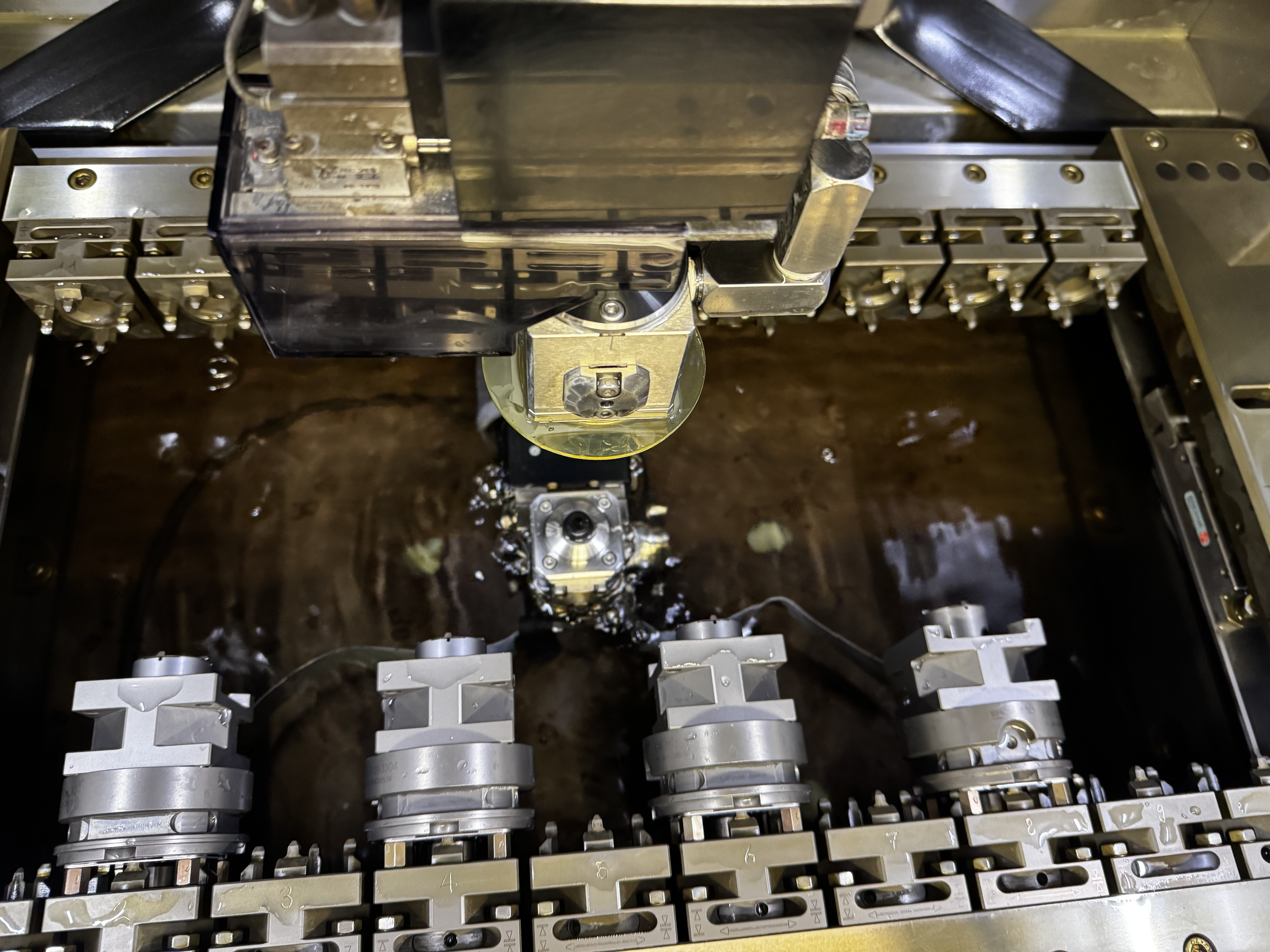

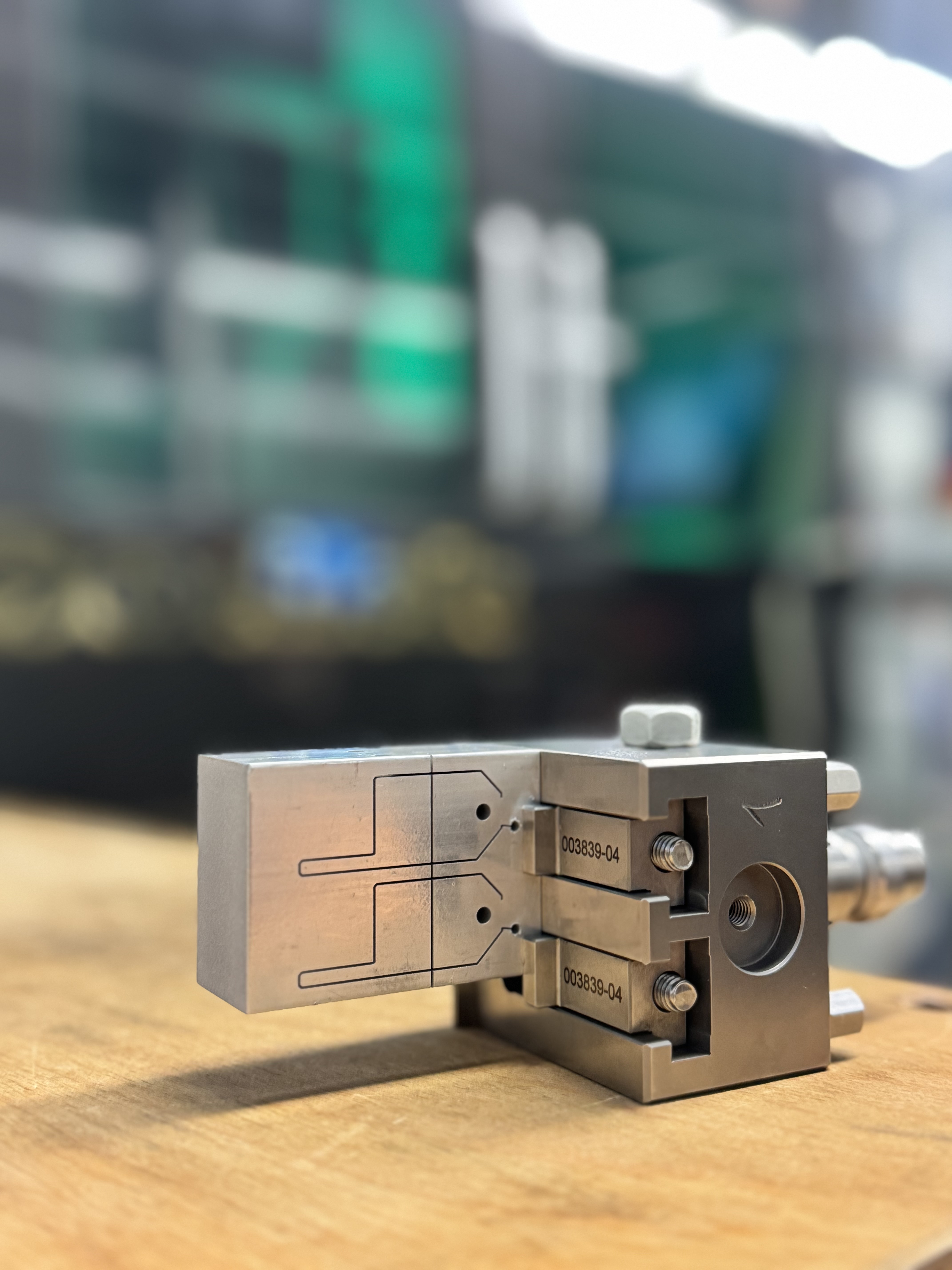

A key highlight of the visit was a tour of EROWA AG in Reinach, where attendees were able to see a sophisticated automated manufacturing cell in operation. The system integrates EROWA’s zero-point clamping and robotic automation technology with two Sodick ALC600P wire EDM machines, demonstrating a high level of flexibility and precision for complex component production.

The project represents the culmination of more than ten years of planning and development, bringing together automation, precision machining, and process optimisation to enable long, unattended production runs while maintaining extremely tight tolerances.

During the visit, Gautschi Beat of EROWA explained the challenges and rewards of operating such a system:

“It’s one thing to automate, but maintaining micron-level tolerances across a wide variety of components during long, unattended overnight runs is another challenge entirely.”

He also highlighted the productivity potential of wire EDM technology compared to traditional machining methods:

“Many shops would be surprised by the productivity of wire erosion compared to 5-axis milling. When you factor in reduced tooling costs, lower energy consumption, and minimal maintenance — combined with high-level automation — the return on investment can be significant. It requires a different mindset.”

The visit provided valuable insight into how automation and EDM technology continue to evolve to meet the increasing demands of modern manufacturing, delivering high precision, repeatability, and operational efficiency.

Sodick Europe continues to work closely with partners and customers across Europe to support manufacturers adopting advanced EDM and automation solutions that improve productivity and long-term competitiveness.